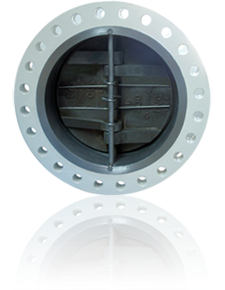

Dual Plate Check Valves

The Dual Plate Check Valve is a multi-purpose valve that is stronger, lighter and smaller compared to conventional swing check or lift check valves.

Design Features:

Separate springs are provided for each door to close. This reduces and overcomes the frictional coefficient due to one plate resting upon another. The spring life cycle is studied and the dynamic behaviour of the valve is recorded. This type of valve prevents flow reversal, functions silently and totally prevents “Water Hammer”. It’s generally light weight, and can be mounted in any direction (Horizontal/Vertical). Also, it has a high CV value and less pressure drop. It’s designed for non-slamming action that prevents premature valve failure, and the valve functions silently for longer duration.

Applications:

Chemicals, Fertilizers, Refineries, Effluent Treatment Plant

Operators:

Automatic Spring return.

Special Features:

Rubber Lined, Soft Seated

Production Capacity: 2"-12" - 150 Nos/Month, 14" & above - 50 Nos/Month |

Material |

Size Range |

Construction |

ANSI Class |

Standard |

Cast Carbon Steel |

2" - 36" |

Wafer / Flanged, |

150# - 2500# |

API 6D / API 594 |

Cast Stainless Steel |

2" - 36" |

Wafer / Flanged, |

150# - 2500# |

|

Cast Iron |

2" - 36" |

Wafer / Flanged, |

125# |

BS 5351 |

Temperature range: -100°C to 600°C

Pressure Rating: Vacuum upto 621 Kg/Cm²

Inspection Std.: API 598

Ends: Flanged, Wafer, Lugged

|